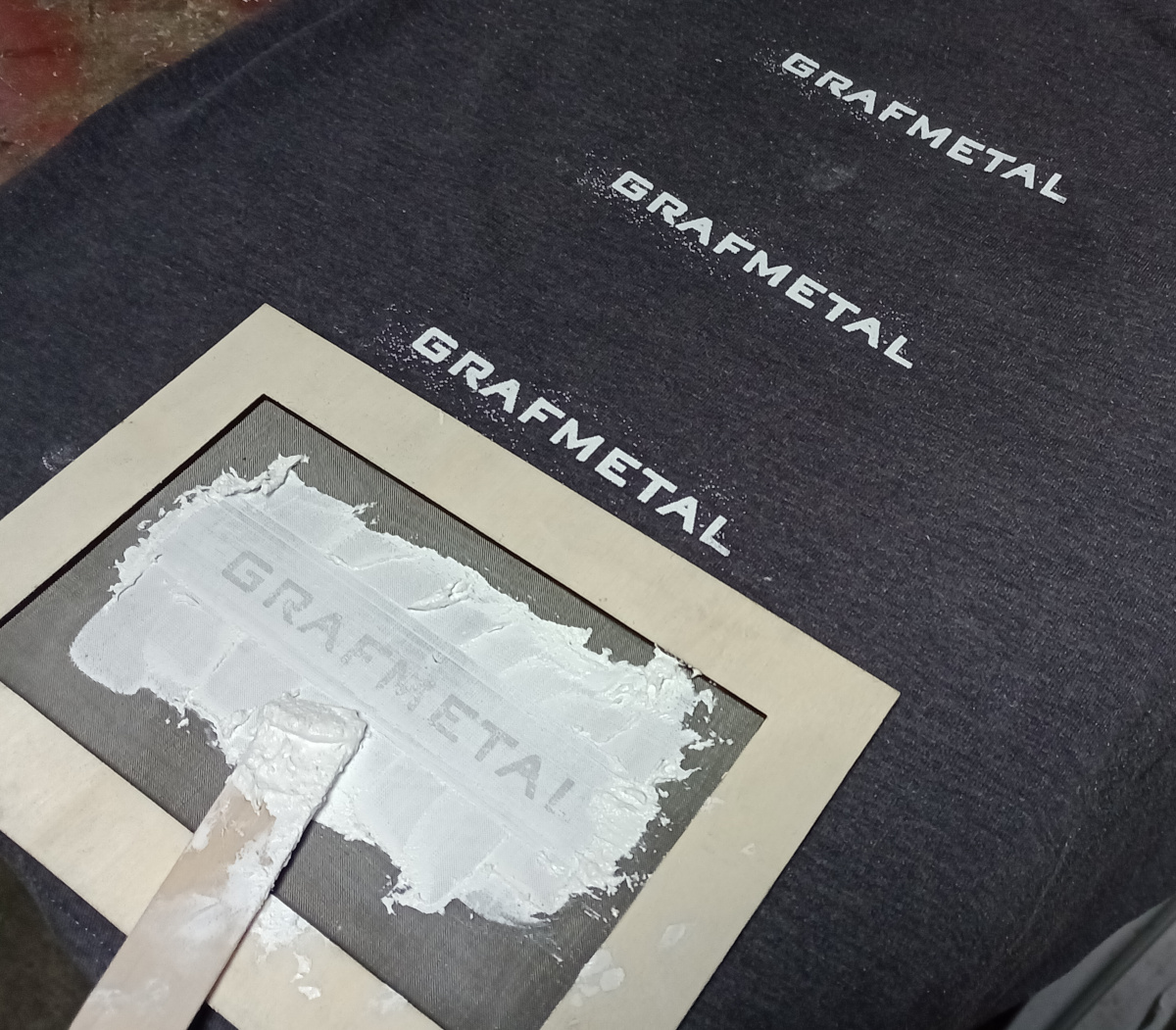

GRAFMETAL metal mesh screen printing lacquer will allow you to use a CO2 laser to make prints on clothing. The lacquer is applied to the metal mesh, and then the desired design is engraved into it.

The lacquer is suitable for working with plastisol paints

The offer is for a package of 25 ml of clear lacquer.

Tha lacquer is used as following:

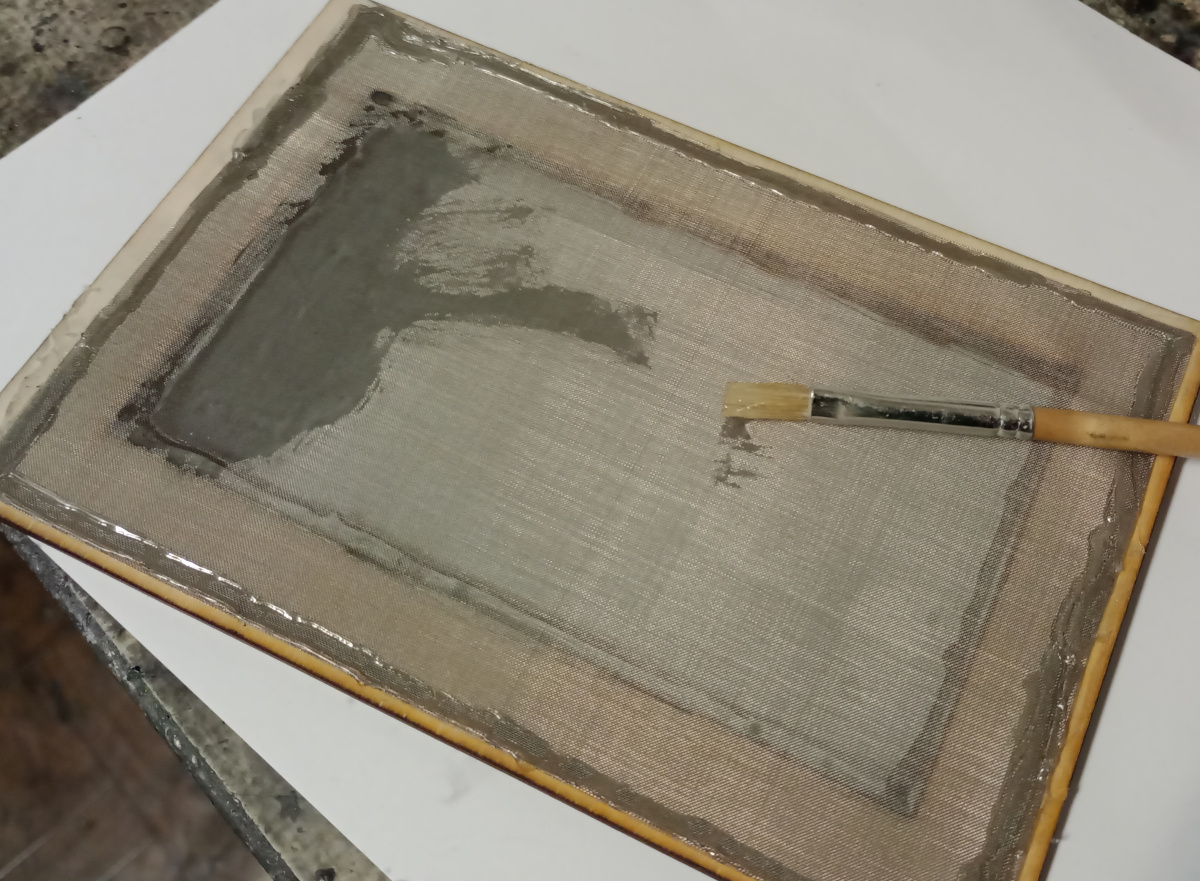

1. One applies the lacquer on the metal mesh. A brush, roller or airbrush can be used for this. The thickness of the lacquer is not as critical as with standard screen printing and photosensitive emulsion.

2. After drying, it is checked under the light to see if the entire mesh has been covered or if any empty spots remain.

3. If necessary, the lacquer is applied again.

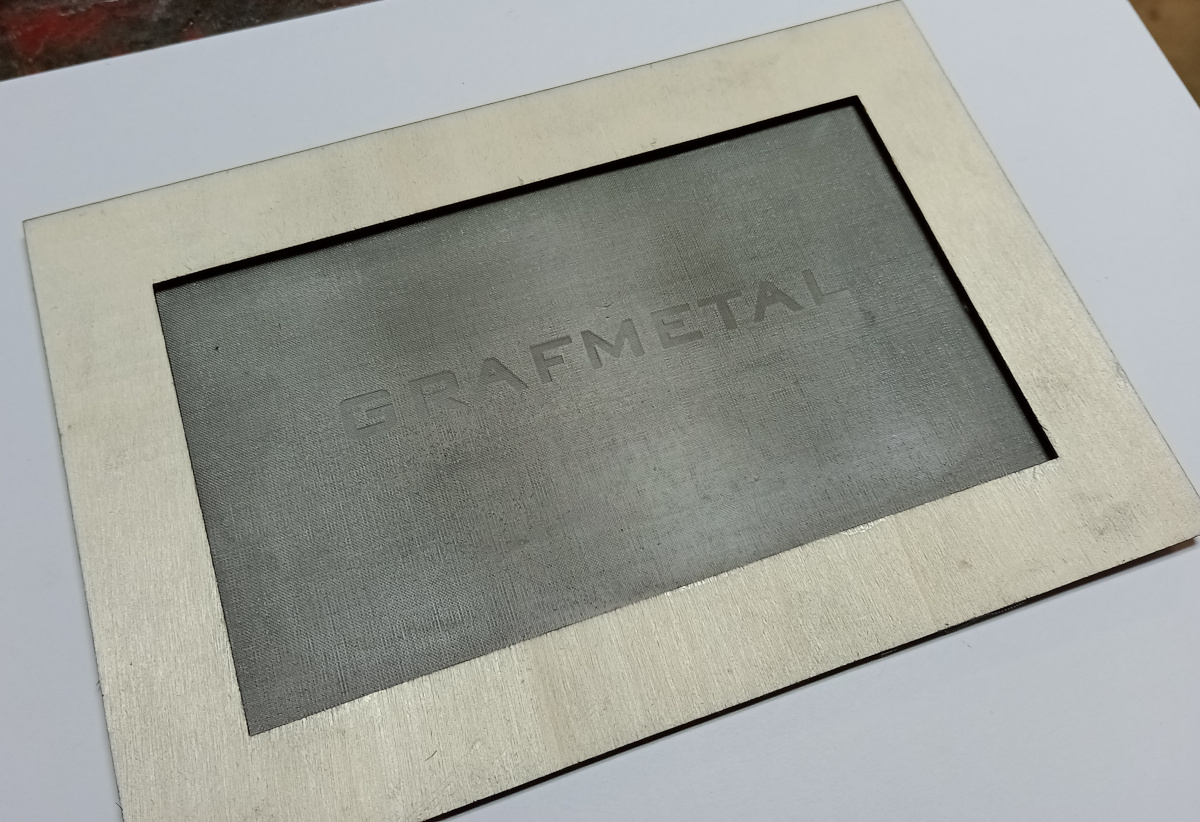

4. A CO2 laser engraves the desired design into the mesh.

Fine mesh meshes generally only need to be coated with lacquer once, while large mesh meshes may require repeating the process.

When engraving a design with a laser, it is best to use a relatively low power and repeat the engraving if necessary to avoid damaging the mesh.

What kind of mesh can be used for screen printing? First of all, commonly commercially available fine woven stainless mesh are good for screen printing, one just needs to select adequate mesh number for a specific print. Sometimes mesh is available under the names: filter mesh or woven stainless mesh. The recommended mesh number is between 30 and 100 per centimeter.

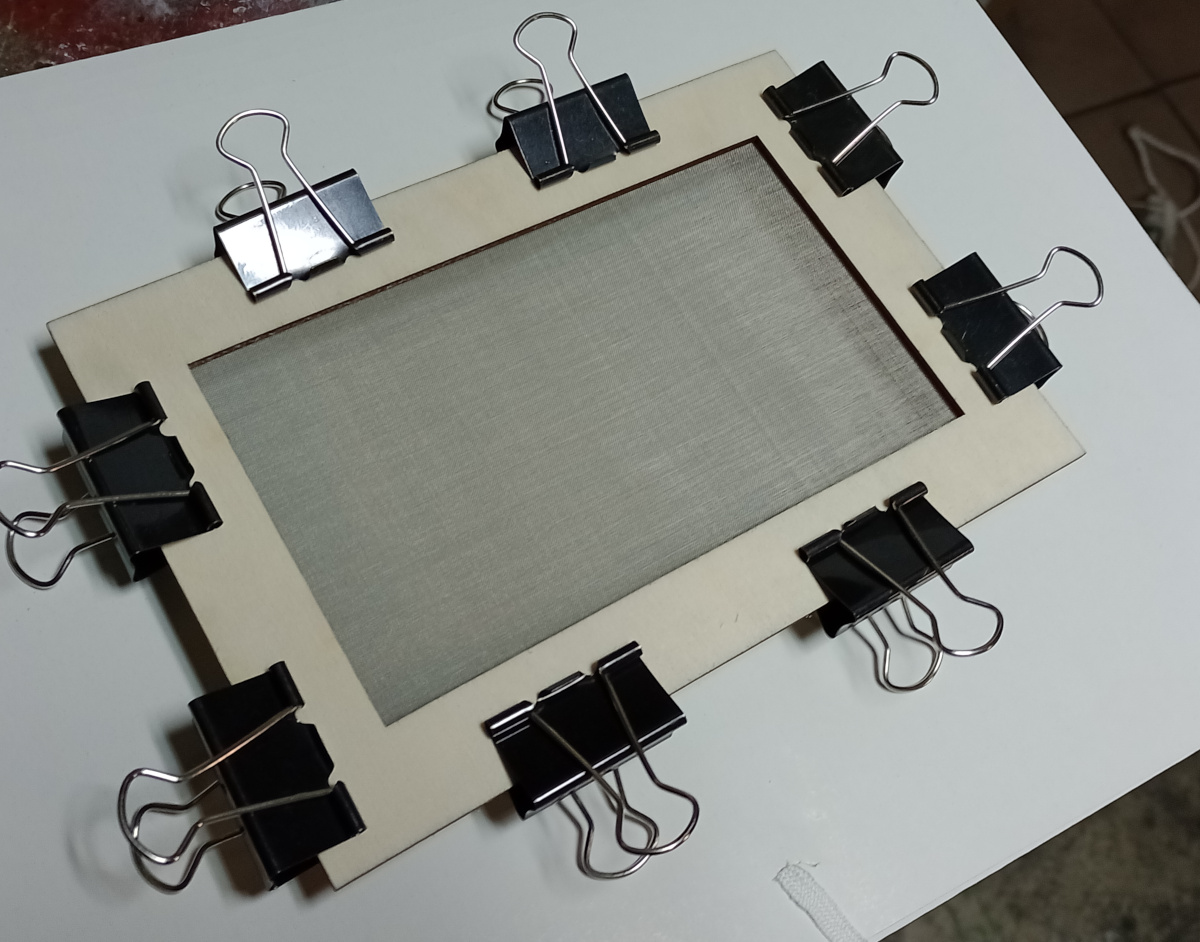

It is worth noting that the frame itself can also be made with a laser, so one can get unusual formats.

After engraving, the mesh is ready for printing. In particular, we recommend GRAFMETAL plastisol inks for that.