The graphite foil offered here is 0.25 mm thick and 1 m wide. It is possible to order pieces with a width of 1 m and a length of at least 1 m.

Parametry folii:

Purity: 99%

Maximum temperature in reducing media: 900°C

Acceptable pH range: 1-14

Density range: 0,7-1,2 g/cm3

Sulfur/chloride content: <1300 / 50 ppm

Tensile strength: > 4 MPa

Losses during roasting (3 h, 450°C): <1%

Leakage under pressure 35 MPa (DIN3535 N2 40 bar): 0.05-0.1 mg/sm

Resistivity (∥/⊥): 12/800 μΩm (przy silnym nacisku)

Heat conductivity (∥/⊥): 180/5 W/(m·K)

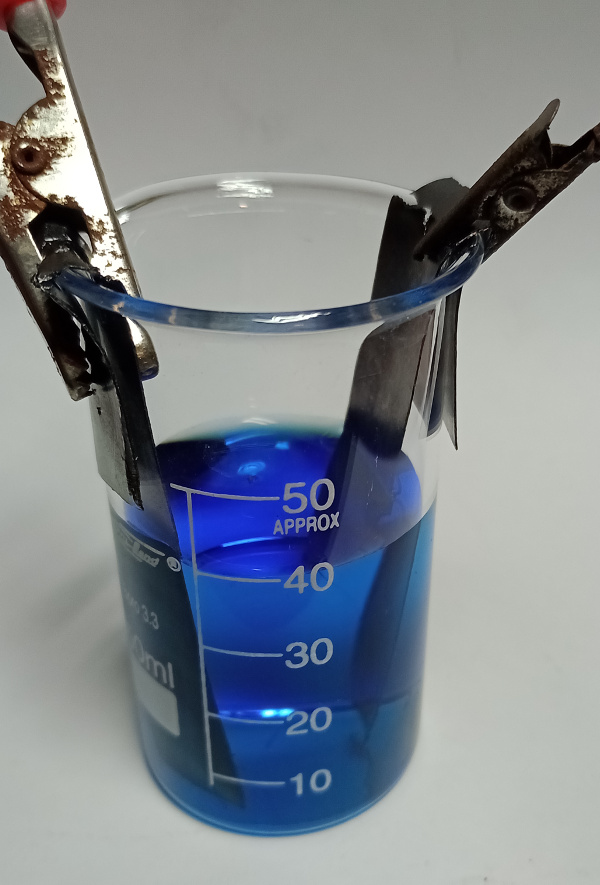

Graphite foil has found a very wide range of applications in sealing, electrical engineering and electrochemistry.

The main application of graphite film is to make gaskets capable of operating over a wide temperature range and in aggressive chemical environments.

In particular, the foil is recommended for head gaskets and similar applications, as the pressure ensures the tightness of the graphite film.

The sheet can withstand very high temperatures in a reducing atmosphere, but for a shorter time it can be used even in the air. It does not ignite when heated briefly to about 900°C.

Graphite foil has very good electrical conductivity. However, contact resistance should be kept in mind and a strong contact should be provided to reduce it.

Graphite sheet is chemically passive and highly conductive, so it can be used to create electrodes, batteries, supercapacitors, fuel cells, etc.

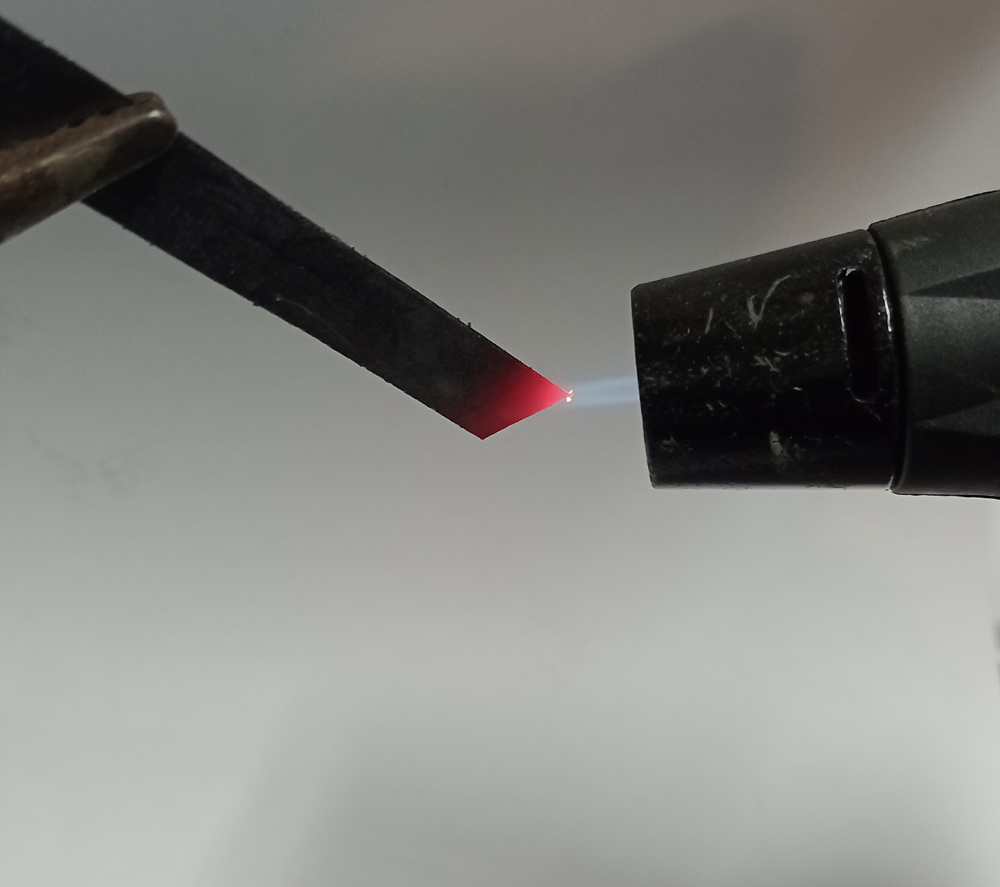

For making parts made of graphite sheet, it is recommended to cut the foil with a knife or similar tools, such as scissors or a rotary knife. Foil is not suitable to be processed with low-power lasers, as it reflects a fair amount of light and conducts heat very well.

The foil is quite fragile and it should not be intended to transfer mechanical stress, as it does not have high tensile strength and it is prone to tearing (it can be torn with hands) and to breaking when sharply bent. It is recommended to use the film as intended or to underlay it with another material if necessary.