GRAFMETAL Protective paste for laser processing of materials allows for protecting engraving laminates, plywood, acrylic and other materials against negative effects of CO2 laser action.

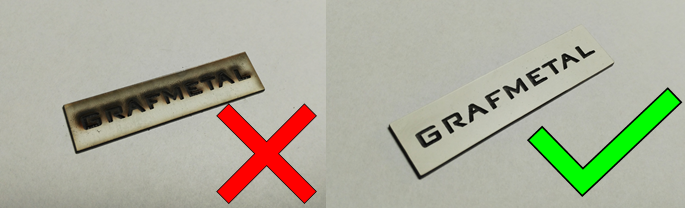

Many CO2 lasers are not able to make nice quality engraving in laminates without staining them, because with "non-dirty" parameters the quality of engraving is poor. Then one has to reckon with the need for time-consuming cleaning of the elements after engraving or peeling off the film or protective paper piece by piece. The solution in such cases is GRAFMETAL Protective paste. The paste protects the laminate from getting stained, as decomposition products are deposited on the paste and not on the laminate. After processing, the paste is conveniently rinsed off with water.

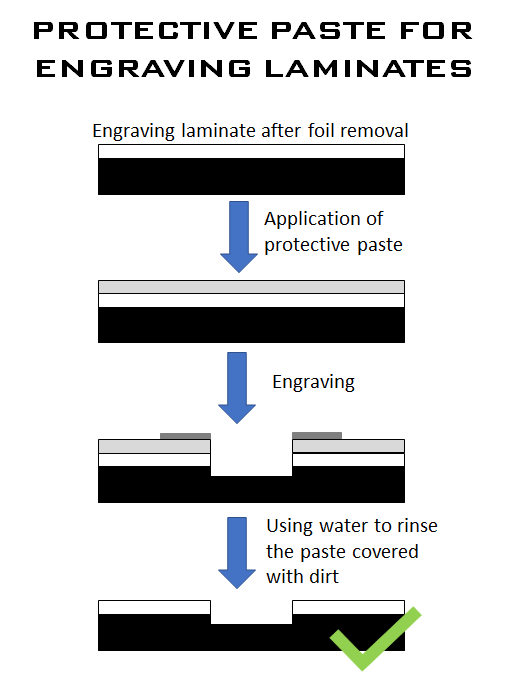

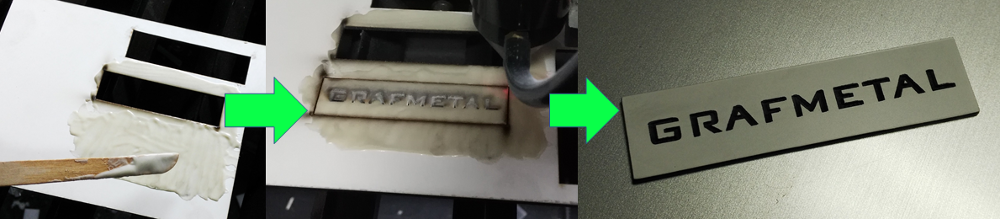

Using the paste is very simple:

1) Removing the protective film from the laminate (if there is one) and apply a layer of protective paste

2) Laser engraving - during engraving, decomposition products are deposited not on the laminate, but on the paste

3) Rinsing the contaminated paste with water

Thanks to using GRAFMETAL Protective paste, you can save your time while achieving high-quality engraving.

Since the paste is an additional layer, one should set higher powers or lower speeds for engraving and cutting then without this paste.

Air blowing at medium or low power will not blow away the paste and is not a problem.

The way the paste works is shown in the pictures below:

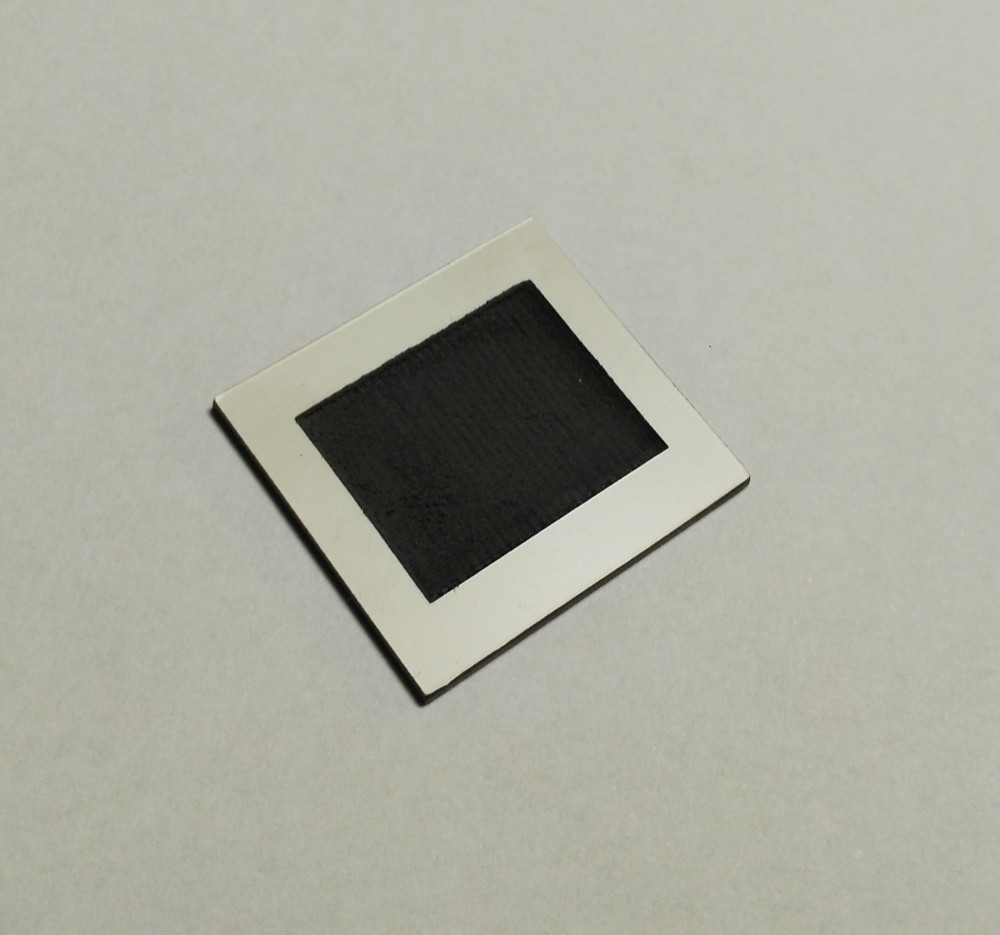

The paste works for both small details and large engraved areas. It is only necessary to adjust the appropriate process parameters. Example parameters for 1.5 mm thick laminate:

Set 1 - low speeds:

80 W x 8% x 100 mm/s (4 in/s) engraving

80 W x 90% x 25 mm/s (1 in/s) cutting

Set 2 - medium speeds

80 W x 24% x 300 mm/s (12 in/s) engraving

80 W x 90% x 25 mm/s (1 in/s) cutting

Various types of laminates can be engraved with the protective paste

GRAFMETAL protective paste also works great when engraving plywood. The element at the top of the photo below was engraved without protection, while the element at the bottom was engraved with a thin layer of protective paste, which was then rinsed off with water.

The yield of the paste is about 250 ml/m2 of protected surface. The paste, which was applied to the surface, but was not stained as a result of laser treatment can be collected and reused. It pays off!