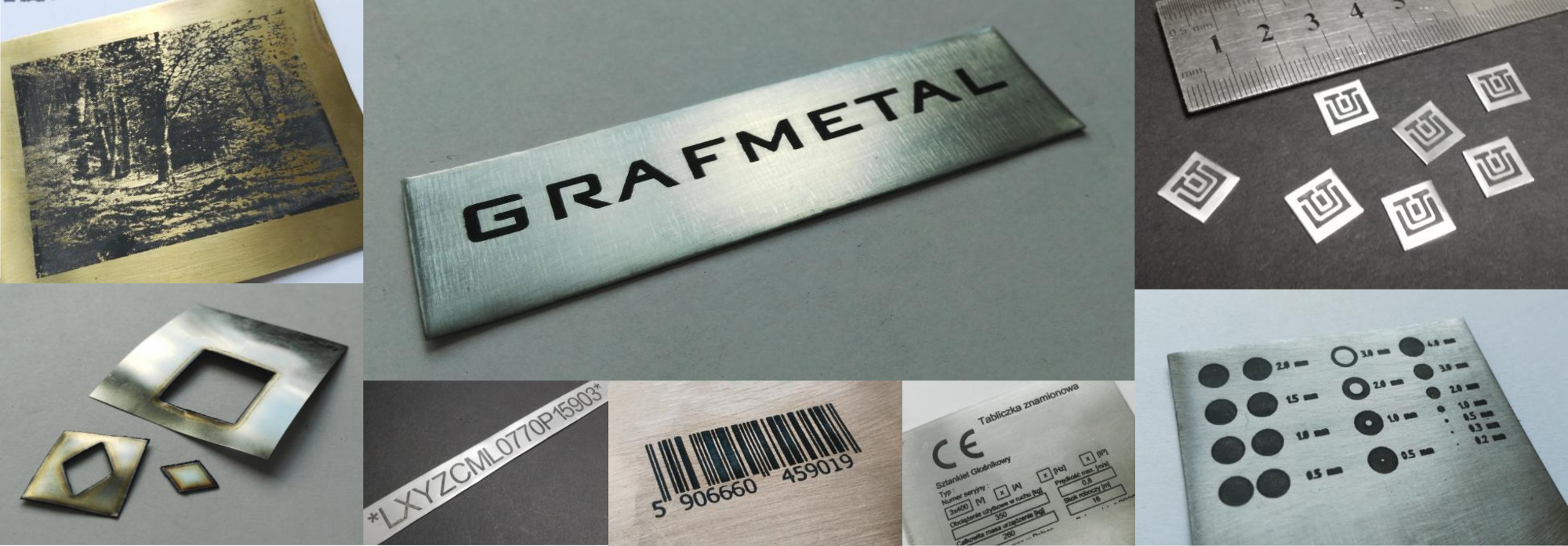

GRAFMETAL universal paste and aerosol are intended to be used for marking metals with ordinary CO2 lasers normally used i.a. for cutting acrylic.

One may find the following GRAFMETAL products for marking metals with lasers:

Universal paste and aerosol: for CO2 lasers, very low cost, marking metals, possibility of steel engraving, possibility of cutting very thin steel sheets, wiping off with a dry cloth or with a paint thinner, greyish-black colour. May be used with high quality diode lasers with at least 20 W of optical power.

Ceramic fluid and aerosol: for CO2 lasers, marking metals, working with high speeds, rinsing with water, black colour. May be used with high quality diode lasers with at least 20 W of optical power.

Fluid for marking of metals with diode laser

Methods of working with each of this product types is different, therefore one may get acquainted with description of them before choosing one.

Apart from that there are also GRAFMETAL products which allow for using lasers to:

chemically etch glass and metal

make prints on clothing

GRAFMETAL universal paste and aerosol are used in a following way:

it is deposited on a metal object to be processed

the object is irradiated with a CO2 laser (right after deposition of a product - it is not needed to wait for drying), air blow does not interfere with laser marking, it may be helpful as it levels paste layer

non irradiated paste is wiped off e.g. with a paper towel, however it can also be collected and used again

The product heats up and cross links when exposed to laser, because of which a greyish-black layer is formed for most metal types. Slower laser runs may allow for engraving of steel. When even slower passes are applied, one may cut very thin steel sheets.

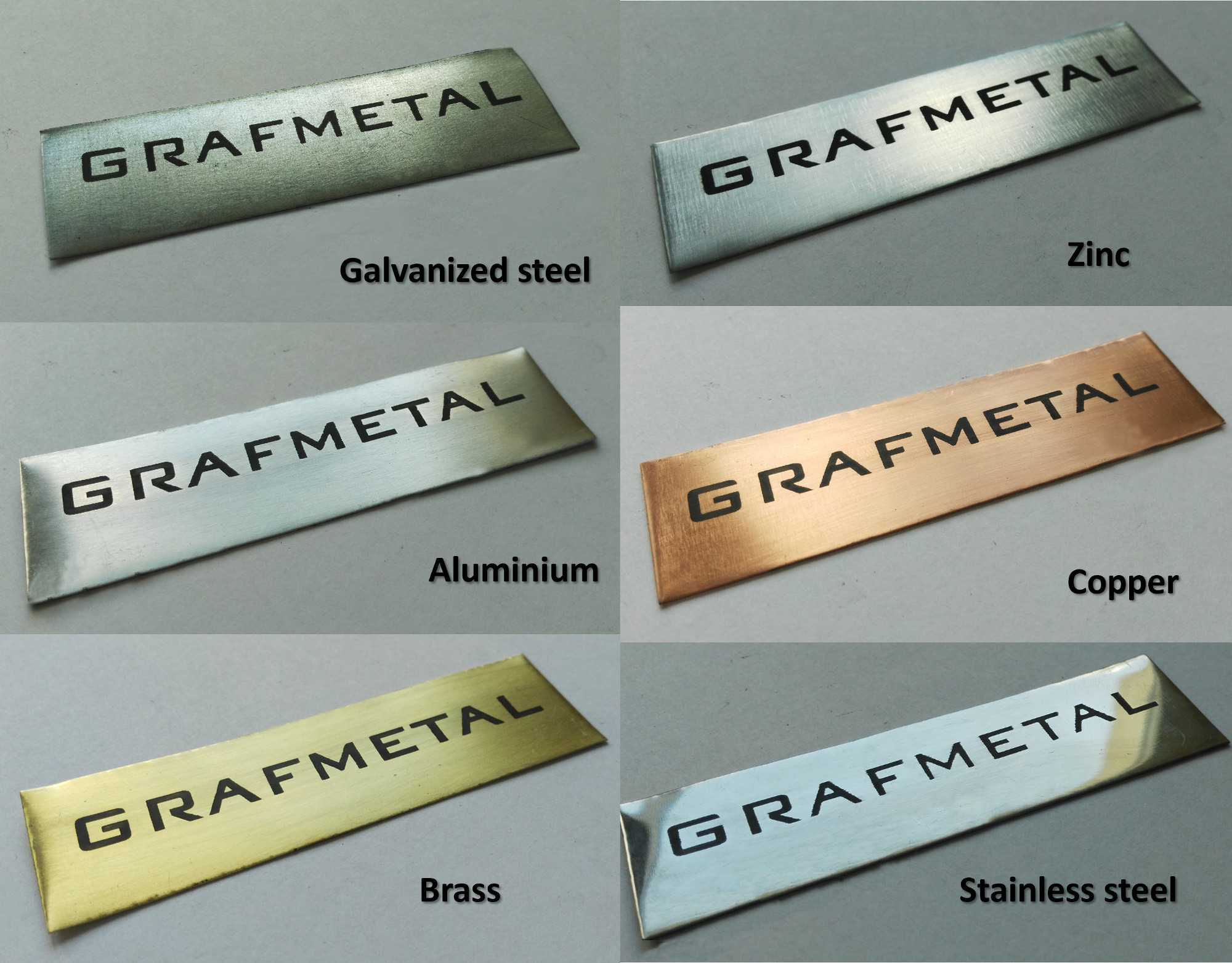

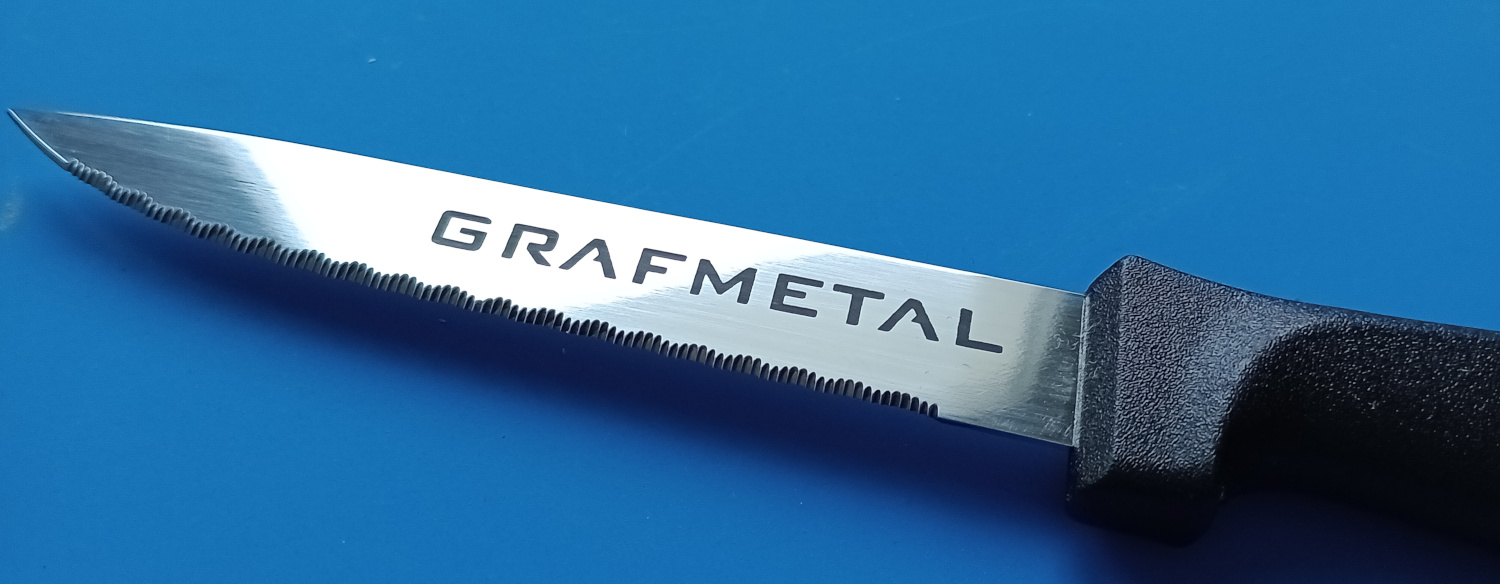

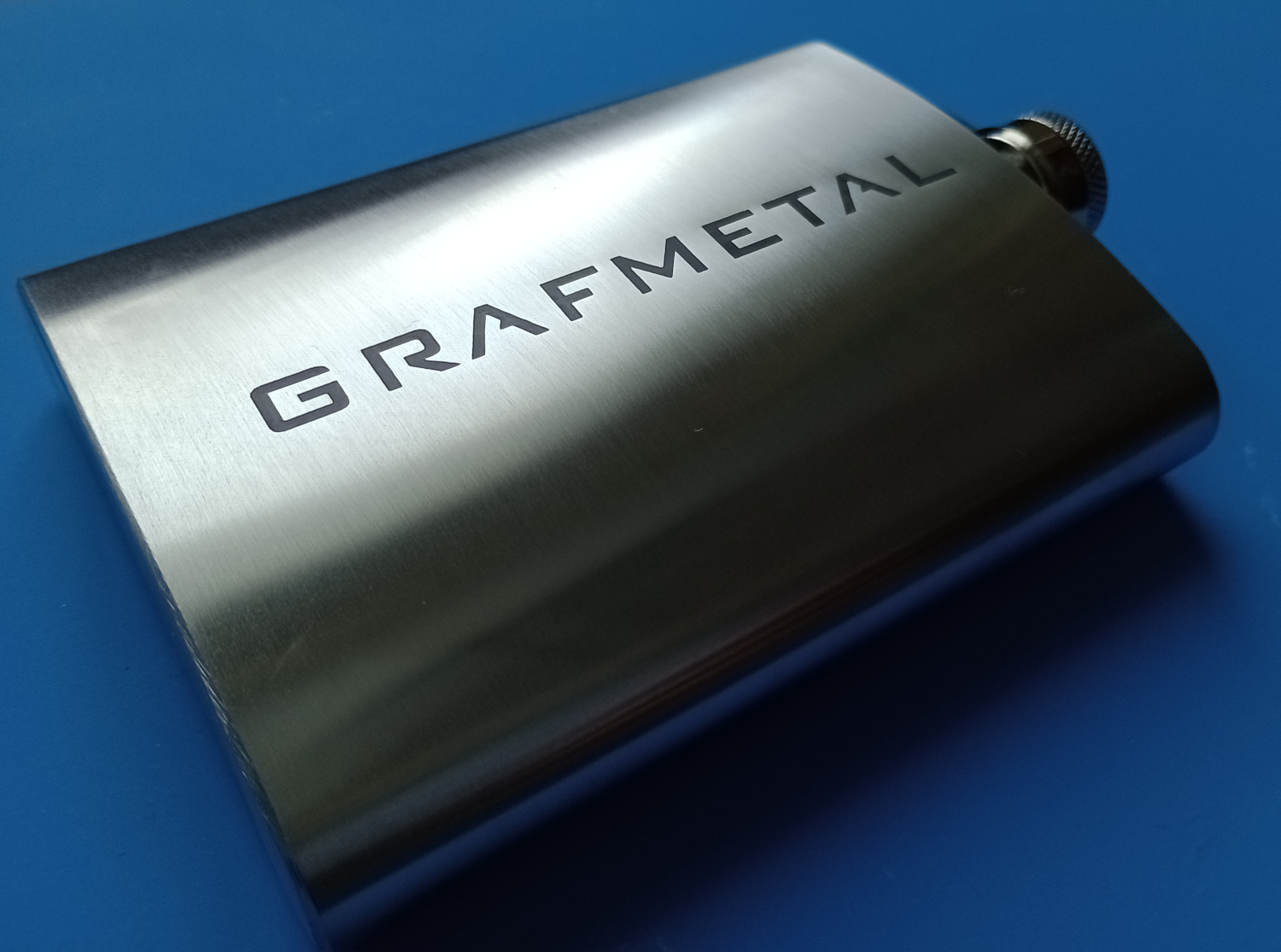

GRAFMETAL universal paste and aerosol may be used to mark most of broadly used metals.

The product may be used both for marking already made metal objects as it may be used for preparing new metal plates. To do that it is needed to cut metal sheet first, which may be accomplished with the following methods:

sheets up to 1.5 mm (0.06") thick (including steel): sheet metal guillotine, electric sheet metal shears

sheets up to 0.5 mm (0.02") thick (including steel): manual sheet metal shears/scissors

sheets up to 0.25 mm (0.01") thick (including steel): tailor shears/scissors

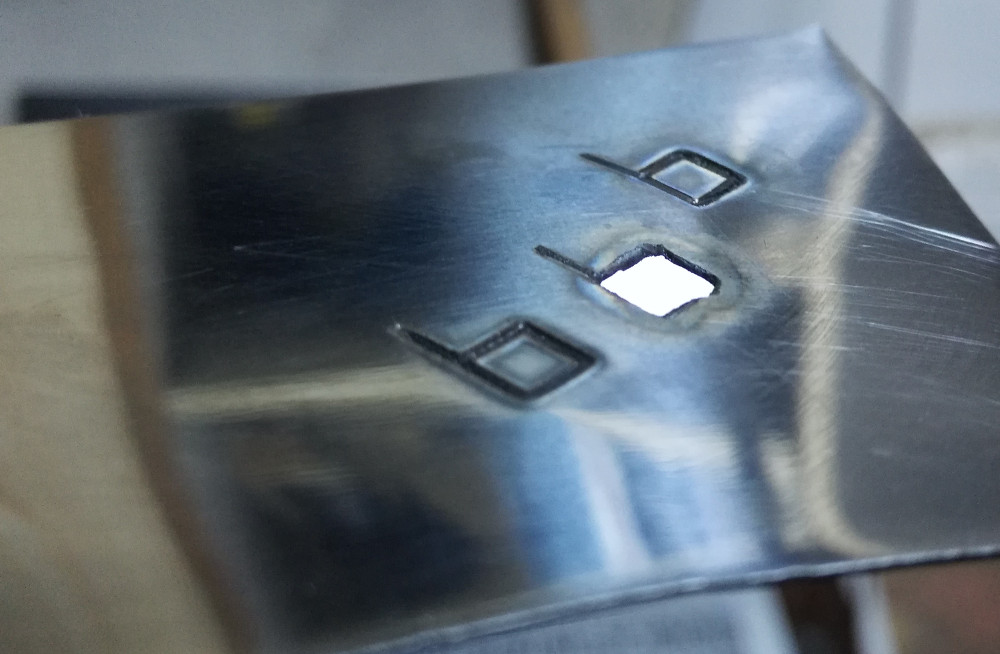

When slower run speeds applied one may engrave steel and stainless steel.

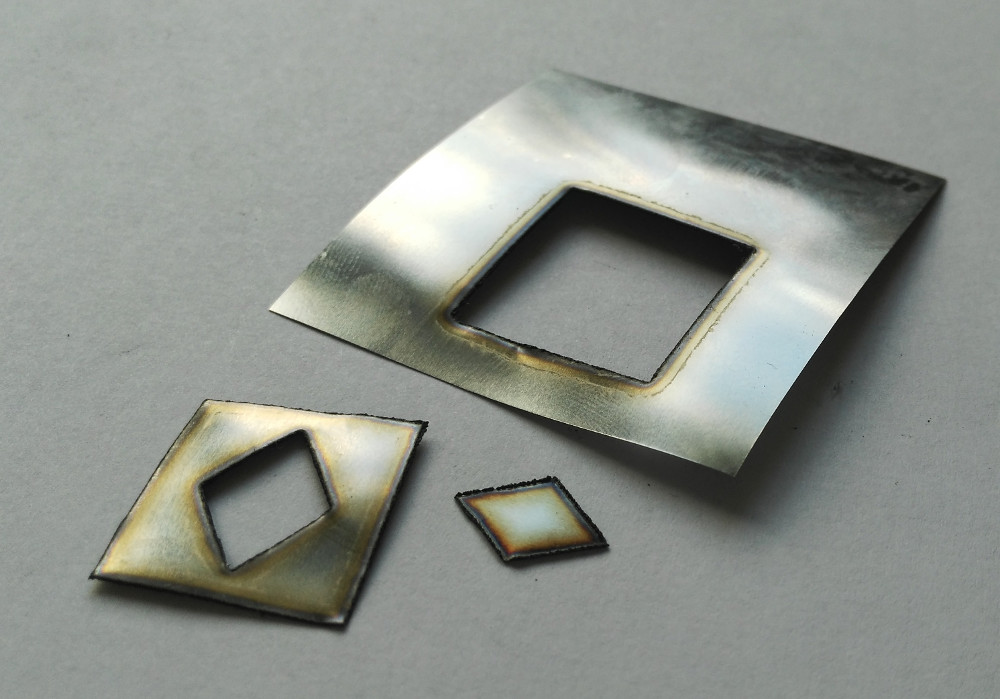

With even slower run speeds it is possible to cut thin steel with a thickness of 0,1 mm (0.004").

It is also possible to cut thicker steels up to 0.5 mm (0.02"), but it requires very slow run speeds.

GRAFMETAL is easy to use and it makes it possible to get very interesting results and fulfil many new orders.

Example processing parameters:

Marking - square with a size between 1x1 mm and 10x10 mm (from 0.04"x0.04" to 0.4"x0.4") :

Steel, stainless steel, acid resistant steel, galvanized steel: 80 W x 50% x 80-120 mm/s (3-4.5 in/s)

Aluminium, copper, brass, zinc: 80 W x 50% x 20-80 mm/s (0.8-3 in/s)

Markings smaller than this range - slower, bigger - faster.

Engraving:

Steel, stainless steel, acid resistant steel, galvanized steel: 80 W x 50% x 20-40 mm/s (0.8-1.6 in/s) or at least 2 runs 80 W x 50% x 40-80 mm/s (1.5-3 in/s)

(reference value: cutting 2 mm (0.08") acrylic - CO2 laser: 80 W x 100% x 30 mm/s (1.2 in/s))

Yield: 6.5-11 m2/liter (72-118 sq ft/liter)

USER MANUAL [EN]

INSTRUKTION [DE]

NAVOD [CZ]

INSTRUCCIÓN [ES]

INSTRUCTIONS [FR]

MANUALE D'USO [IT]

INSTRUCȚIUNI [RO]

Utasítások [HU]

Instruções [PT]

Navodila [SL]

Инструкции [BG]

INSTRUKCJA [PL]

MATERIAL SAFETY DATA SHEET - PASTE

MATERIAL SAFETY DATA SHEET - AEROSOL

KARTA CHARAKTERYSTYKI - PASTA

KARTA CHARAKTERYSTYKI - AEROZOL