Your cart is currently empty!

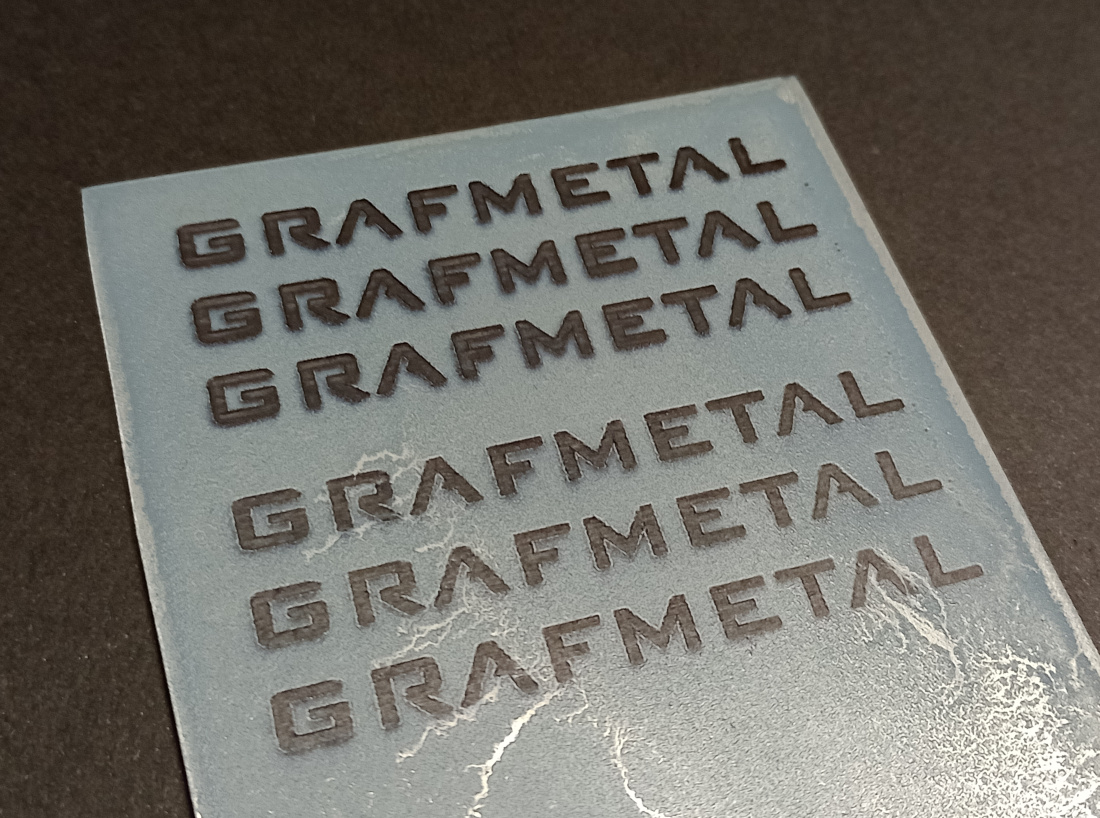

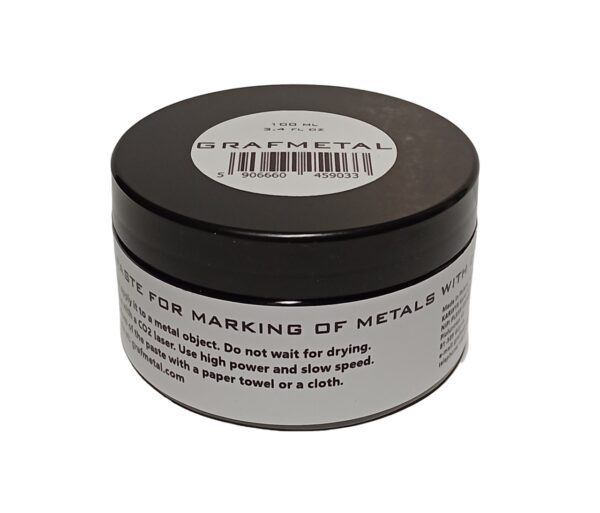

Ceramic rinseable fluid for marking of metals with CO2 laser 100 ml (3.4 fl oz)

GRAFMETAL ceramic rinseable fluid and aerosol are intended to be used for marking metals with ordinary CO2 lasers normally used i.a. for cutting acrylic. One may find the following GRAFMETAL products for marking metals with lasers: Universal paste and aerosol: for CO2 lasers, very low cost, marking metals, possibility of steel engraving, possibility of cutting […]

Description

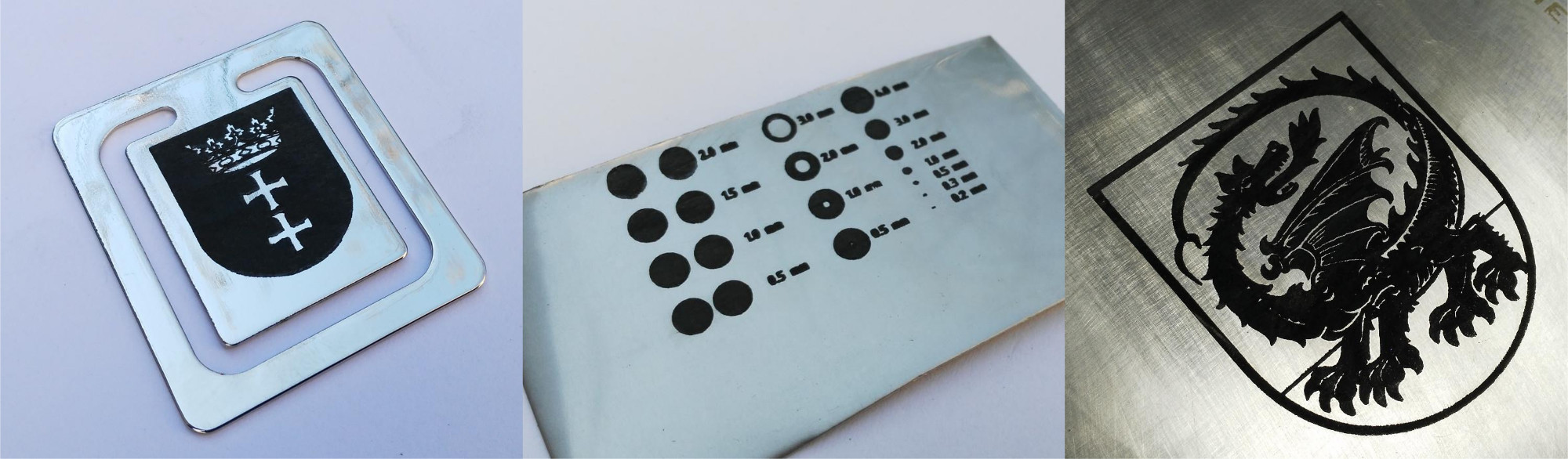

GRAFMETAL ceramic rinseable fluid and aerosol are intended to be used for marking metals with ordinary CO2 lasers normally used i.a. for cutting acrylic.

One may find the following GRAFMETAL products for marking metals with lasers:

-

Universal paste and aerosol: for CO2 lasers, very low cost, marking metals, possibility of steel engraving, possibility of cutting very thin steel sheets, wiping off with a dry cloth or with a paint thinner, greyish-black colour

-

Ceramic rinseable fluid and aerosol: for CO2 lasers, marking metals, working with high speeds, rinsing with water, black colour

Methods of working with each of this product types is different, therefore one may get acquainted with description of them before choosing one.

GRAFMETAL ceramic fluid and aerosol allow marking most metals at high speeds, making it particularly useful for those customers for whom processing time is of the utmost importance. Apart from that the residues may be rinsed off with water, which saves even more time.

GRAFMETAL ceramic rinseable products are used in a following way:

-

Fluid or aerosol need to be stirred well first

-

Then one applies them on a metal object to be processed and waits 10 min for drying

-

The object is irradiated with a CO2 laser

-

Non irradiated paste is rinsed off with water

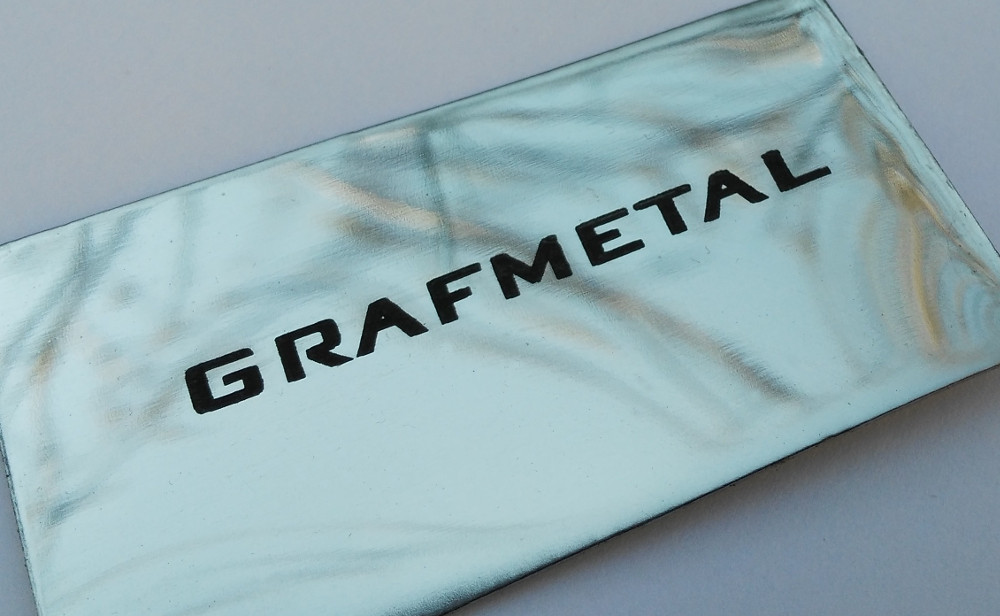

The layer heats up and hardens when exposed to laser light, resulting in a black layer that gives a marking effect on most types of metals.

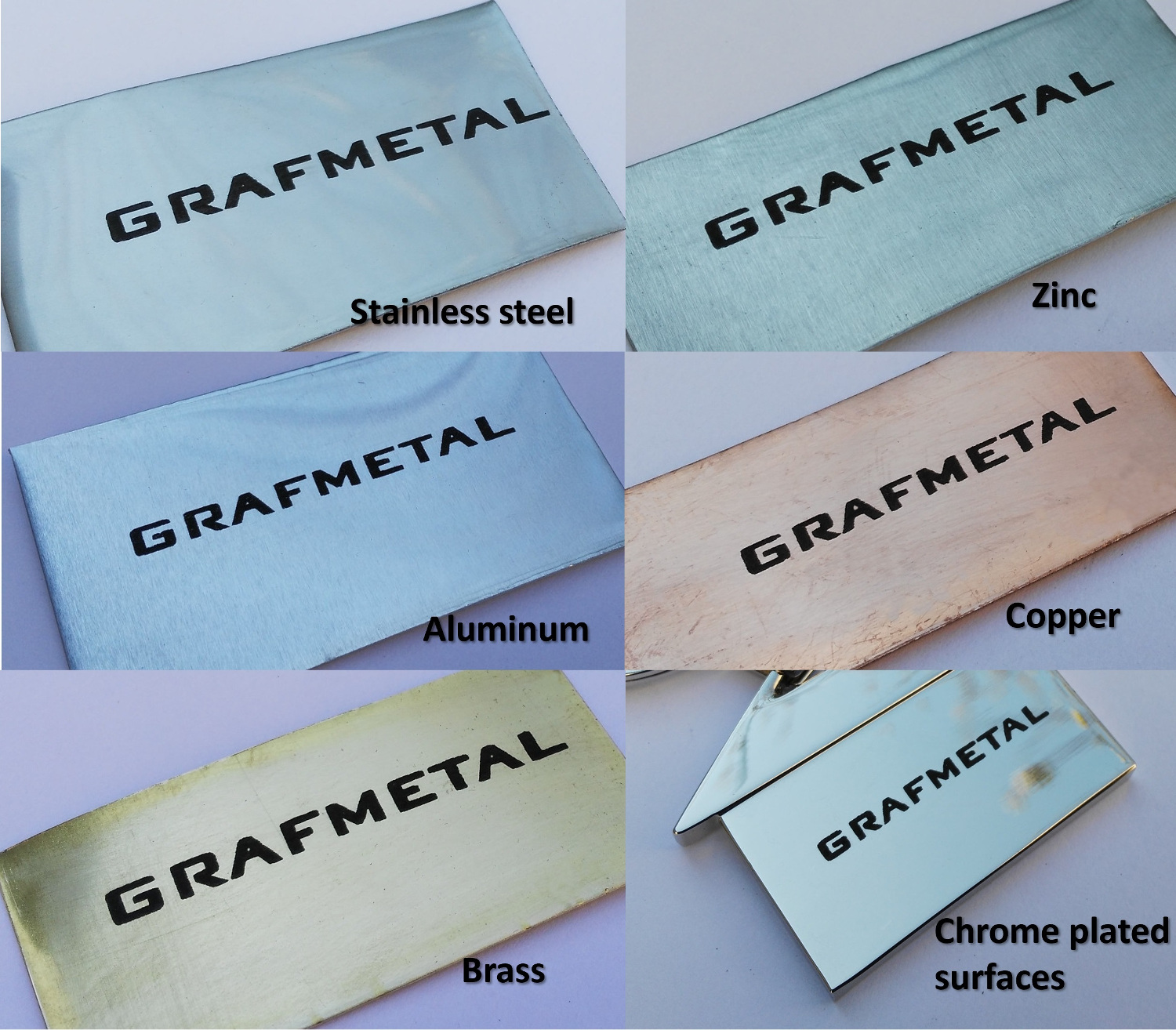

GRAFMETAL ceramic rinseable fluid and aerosol can be used to mark most commonly used metals.

The product may be used both for marking already made metal objects as it may be used for preparing new metal plates. To do that it is needed to cut metal sheet first, which may be accomplished with the following methods:

-

sheets up to 1.5 mm (0.06″) thick (including steel): sheet metal guillotine, electric sheet metal shears

-

sheets up to 0.5 mm (0.02″) thick (including steel): manual sheet metal shears/scissors

-

sheets up to 0.25 mm (0.01″) thick (including steel): tailor shears/scissors

Ceramic rinseable fluid and aerosol allow permanent marking of chrome surfaces, even without degreasing.

Ceramic rinseable fluid and aerosol can be used to mark finished metal objects.

Aluminum processing is not a problem.

GRAFMETAL ceramic rinseable fluid and aerosol are easy to use, and with it you can get very interesting results and fulfil many new and interesting orders.

Example processing parameters:

Steel, stainless steel, acid resistant steel, galvanized steel: 80 W x 100% x 300-500 mm/s (12-20 in/s)

Aluminum, copper, brass, zinc: 80 W x 100% x 100-400 mm/s (4-16 in/s), The better cleaned or rougher the surface, the higher speed can be used, for example, aluminum after cleaning with 2500 grade sandpaper: 200-400 mm/s (8-16 in/s), aluminum with mirror finish: 100-150 mm/s (4-6 in/s)

Chrome plated surfaces: 80 W x 100% x 50-150 mm/s (2-6 in/s)

(reference value: 2 mm (0.08″) thick plexiglass cutting – CO2 laser, 80 W x 100% x 30 mm/s (1.2 in/s))

Yield (fluid): 6-10 m2/liter (64-110 sq ft/liter)

Yield (aerosol): 0.7-1 m2/400 ml container (7.5-11 sq ft/container)

Additional information

| Weight | 0.5 kg |

|---|---|

| Dimensions | 15 × 15 × 6 cm |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.