GRAFMETAL fluid for marking of metals with diode laser is intended to be used for marking of metals with devices utilizing blue laser for engraving. Fluid works with devices with at least 1 W of optical power, for faster work minimum 5 W is recommended. Fluid is not intended to be used with CO2 lasers. Layers after being cured with a laser from engraving machine are durable and water resistant, but they can be washed off with a solvent if needed.

One may find the following GRAFMETAL products for marking metals with lasers:

Fluid for marking of metals with diode laser: for blue diode lasers, marking of metals, graphite black colour

Pastes, fluids and aerosols for marking of metals with CO2 lasers. May be used with high quality diode lasers with at least 20 W of optical power.

Sposób działania i postępowania z każdym z tych rodzajów produktów jest różny, więc zapraszamy do zapoznania się z opisami obu przed dokonaniem wyboru.

Methods of working with each of this product types is different, therefore one may get acquainted with description of them before choosing one.

chemically etch glass and metal

make prints on clothing

GRAFMETAL fluid for marking of metals with diode laser allows for marking of majority of metal by using diode laser engraving machines with low optical power, even from 1 W!

GRAFMETAL fluid for marking of metals with diode laser is used in a following way:

Stir the fluid very thoroughly. If it is too viscous, then dilute it with alcohol. Alternatively one can use water for dilution, but it may increase substantially the drying time.

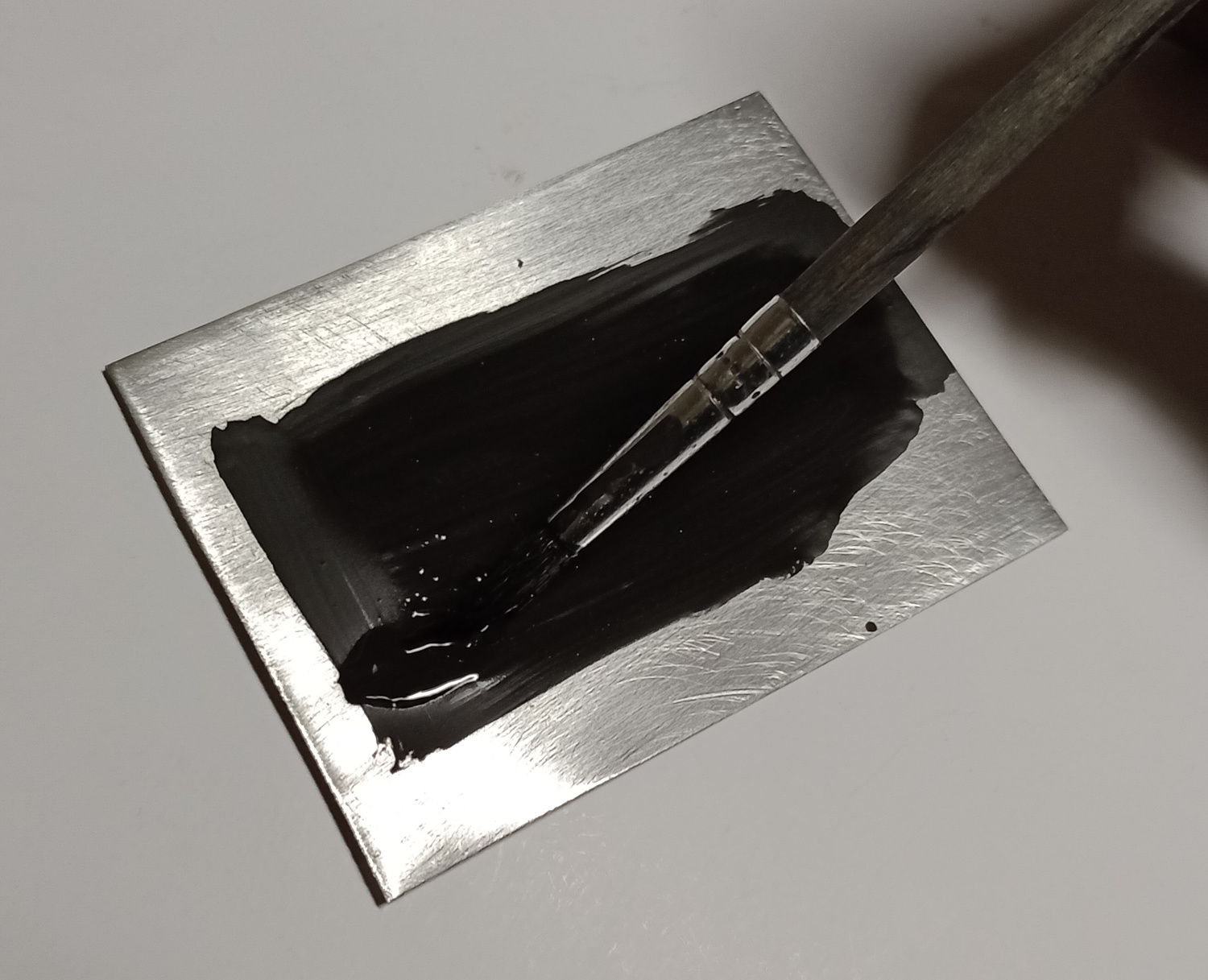

Right after stirring deposit a uniform and thin layer of preparation on the surface of a metal object with a spatula or a hard brush. Wait at least 10 min for drying.

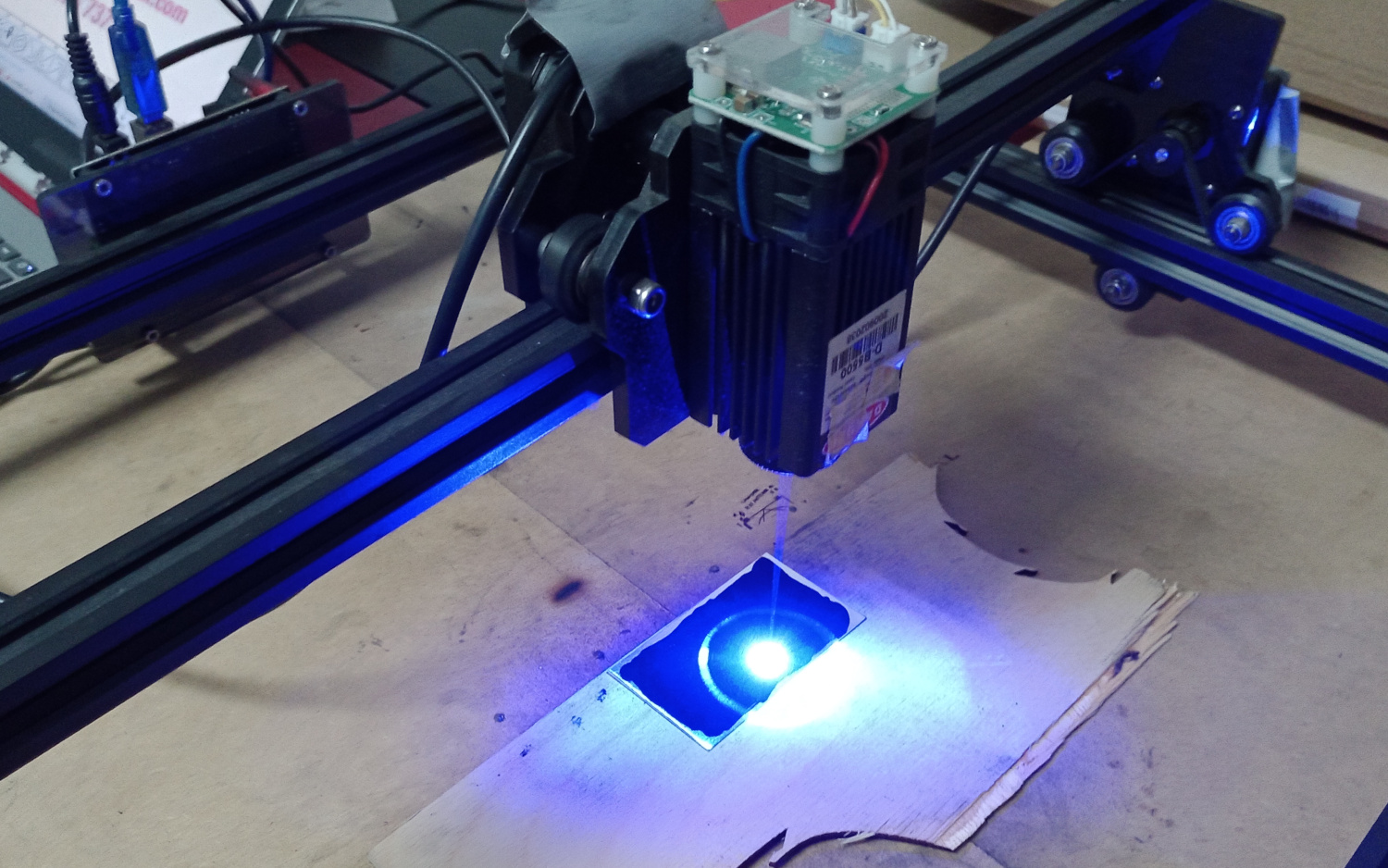

Take care of safety when working with a laser and burn the pattern with a diode laser.

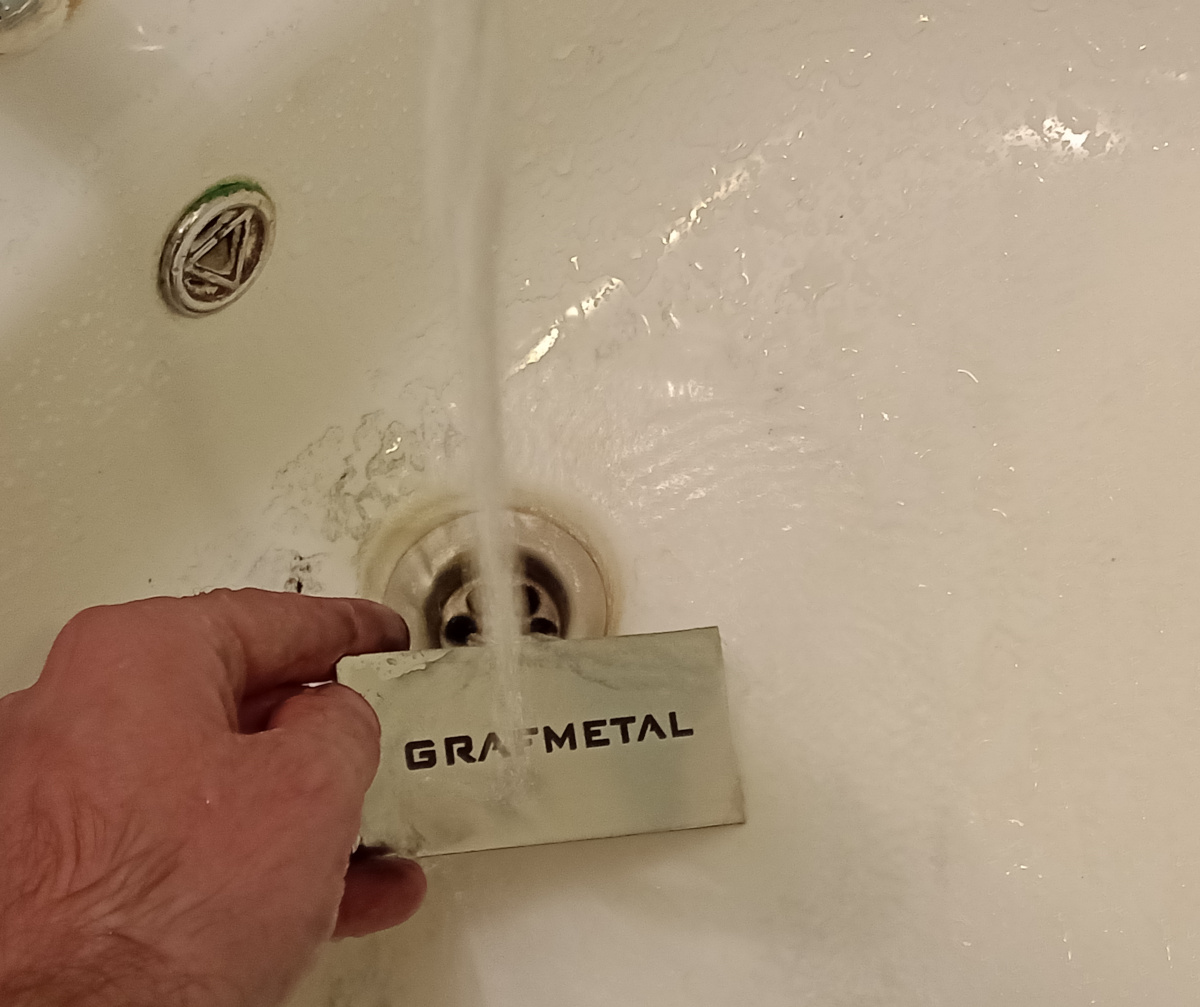

Rinse or wipe off the unburnt paste.

The fluid heats up and cures when irradiated with laser light, what produces a black layer, which gives a marking effect on majority types of metals.

The preparation does not dissolve in water after curing with laser, but it may be removed with a solvent, e.g. with acetone.

GRAFMETAL fluid for marking of metals with diode laser can be used for marking of majority of broadly used metals.

Aluminium processing is not a problem, which is shown below.

The product may be used both for marking already made metal objects as it may be used for preparing new metal plates. To do that it is needed to cut metal sheet first, which may be accomplished with the following methods:

sheets up to 1.5 mm (0.06″) thick (including steel): sheet metal guillotine, electric sheet metal shears

sheets up to 0.5 mm (0.02″) thick (including steel): manual sheet metal shears/scissors

sheets up to 0.25 mm (0.01″) thick (including steel): tailor shears/scissors

GRAFMETAL fluid for marking of metals with diode laser makes it possible to permanently mark the surface of various types of metals, including stainless steel.

The fluid may be easily applied to a metal object, e.g. with a paint brush.

Burning is carried out with ordinary blue laser engraving machines.

The unbrunt paste may be removed after laser processing by wiping or rinsing off with water.

It is possible to produce photographic images after a proper image processing.

It is necessary to note that spot size achieved by using this fluid will be broadened in comparison to what is obtained when engraving e.g. plywood.

The product can be used for black marking of glass and some other non-metalic materials.

Example parameters: blue diode laser (approximately 450 nm) with 5 W of optical power, 100% of power (static M3), 600 mm/min speed.

Additional remarks: if the adhesion is too weak, then increase power and/or reduce speed. If the layer is not uniform, then dilute the fluid. Metal objects with higher heat conductivity (e.g. copper, aluminium, brass or thicker objects) should be processed at lower speed and higher power. Patterns burnt with laser may be rinsed off with acetone. Yield up to 5 m2/L.

You can watch video manual below:

USER MANUAL [EN]

Instructions [FR]

Instrucciones [ES]

Manual de utilizare [RO]

Utasítások [HU]

Navod [CZ]

Navod [SK]

INSTRUKCJA [PL]